Energy

As a manufacturer and producer, we have a particular responsibility to protect both the environment and our climate. We take our environmental responsibility seriously and strive every day to play our part. Making a conscious effort to use valuable energy sources carefully is as fundamental to us as covering our energy requirements with renewable energy sources. During our development phase, as well as when procuring raw materials, we always look for the best solution in ecological terms.

We have installed state-of-the-art photovoltaic units at our Augustdorf and Detmold sites which supply electricity to our manufacturing facilities and feed unused energy to the public network. On average, we produce a total of approximately 950,000 kWh every year.

By way of comparison, this amount of solar energy would power more than 200 electric cars for a whole year.

By generating our own energy using solar systems and the energy station in Augustdorf, as well as purchasing climate-neutral energy, we have been able to reduce the carbon footprint of the sites by around 6,500 tonnes of CO2 equivalents compared to the use of conventional energy sources.

Energy

Manufacturing industrial products is just not possible without energy. But even energy is a finite resource. It is therefore particularly important to us that we use this resource responsibly. This includes constantly looking for opportunities to save energy as well as examining the source of our energy in terms of where it comes from. We are constantly working to improve in this area. Amongst other things, we have worked for many years on the DIN EN ISO 50001, improving our energy efficiency and have since been able to implement a systematic energy management system.

Using energy responsibly

We have reduced our electricity consumption considerably by converting the lighting in our production facilities at Augustdorf to LED and by fitting energy-saving motors in all our machines. We have also been able to reduce the volume of forklift traffic at all our sites through our electromobility concept and by automating transport routes. Since 2017, we have also been using climate-neutral electricity (100% CO2 neutral) from the Detmold municipal facilities for the manufacture of our polyurethane flooring.

Producing our own energy

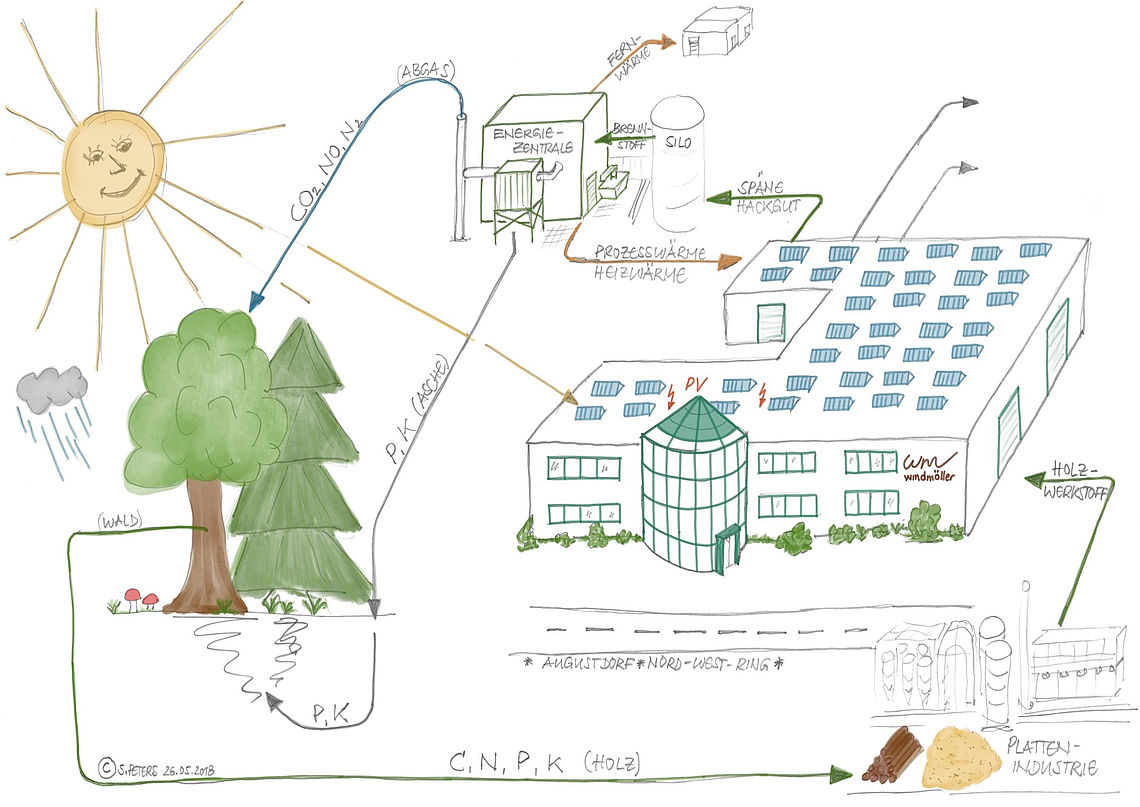

We are now able to work more sustainably than ever before not just because we have reduced our energy use but also because we now produce our own energy. Our cogeneration plant in Augustdorf has been using production residues since 2018 to produce process and heating energy.

We now have a closed energy circuit thanks to the new power plant at the Augustdorf site.

The Augustdorf power plant

Our aim is to make the Augustdorf site's electricity and heat supply as sustainable and autonomous as possible. To this end, production waste is burnt in the power plant and the energy subsequently produced is reused. The majority of this energy is fed directly back into production as process and heating energy. The excess energy which cannot be used in manufacturing is fed back into the local district heating network.

Tied into nature’s cycle

The special feature of the combined heat and power plant in Augustdorf is that it is integrated into the natural cycle and thus operates in a particularly environmentally friendly manner. The waste from our own production is used to generate energy. The energy produced by burning these wood chips is then taken from heat converters and returned as process energy. Excess energy can also be stored in a 200 m3 buffer storage facility. The waste products from the incineration process such as carbon dioxide, phosphorous or potassium are then be returned to nature as important nutrients.

Sustainability and Efficiency in Focus: Our ISO 50001 Recertification

At Windmöller, we are committed to a sustainable and energy-efficient future. We are proud to announce the successful recertification of our energy management system according to ISO 50001. This internationally recognized certification confirms our systematic efforts to continuously optimize energy consumption, conserve resources, and reduce emissions.

By implementing innovative measures and regularly reviewing our processes, we not only meet the requirements of the standard but also go a step further: we invest in forward-looking solutions to contribute to climate protection and offer our customers sustainable products.

The certificate symbolizes our commitment to acting responsibly and ensuring the highest standards in energy efficiency.

Learn more about our sustainability strategy and take a look at our current ISO 50001 certificate.

Together, we are shaping a more environmentally conscious future – step by step, with every kilowatt hour saved.

Environmental Policy

What does our environmental policy include?

Our environmental policy is a central component of our corporate strategy. It defines how we as a company assume our responsibility towards the environment and promote sustainable practices. The environmental policy includes measures to reduce our ecological footprint, promote resource efficiency and support environmental initiatives.

Download our complete environmental policy as a PDF to find out more about our measures and objectives:

Why do we have an environmental policy?

- Responsibility and sustainability: We are aware of our responsibility towards the environment and are actively committed to the protection and conservation of natural resources.

- Innovation and efficiency: We strive to make our processes more efficient and environmentally friendly through sustainable practices and innovative solutions.

- Transparency and commitment: We communicate openly about our environmental goals and achievements and encourage our employees and partners to become involved in environmental protection.

- Securing the future: By making sustainable decisions today, we are securing the future of our company and helping to create a world worth living in for generations to come.